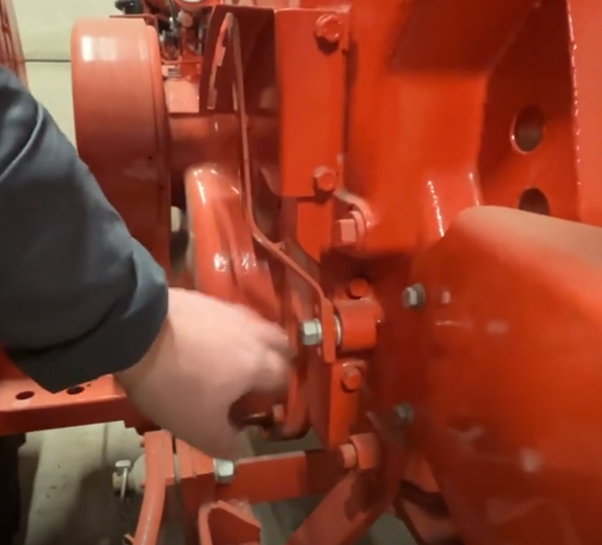

The eagle-eyed of you may have noticed that earlier this week I put up a couple of new videos on our Tractor Spare Parts Ltd You Tube channel. One of these videos showed Andy pointing to our own Universal 3 and showing where the PTO selector lever is to the left-hand side of the seat. We had a customer who had a leak on this PTO selector shaft and wanted to know how easy it is to stop the leak. I thought that this was a very good question and thought I would document this in this week’s blog

Below is a picture of the leak that the customer was dealing with. This is a still from a video that the customer sent me. We always like to receive photos and videos as they really make sure that we know that we are all talking about the same part of the tractor – especially when there is a language barrier too!! Not that this particular tractor owner has a language barrier, as this Nuffield is located in South Africa, but even in the English language different countries and dialects have different names for different parts of the tractors e.g. fender is the American word used for mudguard.

Thankfully this leak on the PTO lever is a relatively easy to repair, it involves the replacement of an O-ring, which is part number NT3383, and is readily available from our website, www.tractorspareparts.co.uk by following this link.

This is relevant to all the Nuffield tractors, the Leyland middleweight tractors, the Leyland Heavyweight tractors, and the Golden Harvest Marshall tractors. So, the full compliment of models and is also applicable to the single-speed and 2-speed PTO tractors.

The following models of tractor are fitted with the NT3383 O-ring:

Nuffield M4, PM4, DM4

Nuffield 3DL, 4DM, 342, 460, 10/42, 10/60, 3/45, 4/65

Leyland 344, 384, 253, 255, 270, 245, 262, 462, 272, 472, 282, 482, 285, 485, 2100, 4100

Marshall 502, 602, 604, 702, 704, 802, 804, 904XL, 954XL

The problem and why the PTO selector leaks

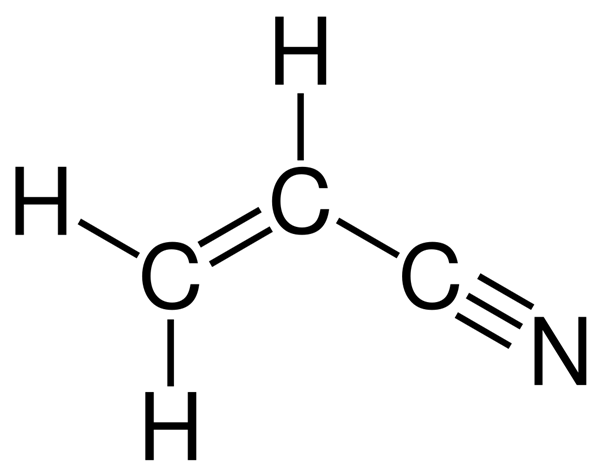

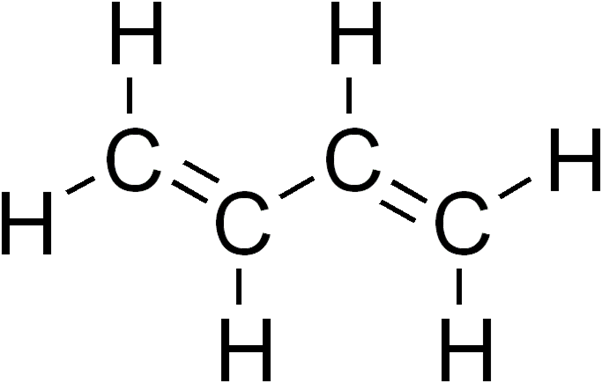

O-rings are typically made of nitrile rubber although other materials can be used. Nitrile rubber (also known as NBR or nitrile butadiene rubber) is a synthetic rubber made of acrylonitrile and butadiene. It is often used for hoses, seals, and also protective gloves (nitrile gloves).

Nitrile rubber is the material of choice for most O-rings because it has good mechanical properties, has resistance to greases and lubricants and is a relatively low-cost material.

The chemist in me is fascinated by how physical properties can arise from different chemicals, but I will not bore you too much, just a little bit I promise.

Nitrile rubber gets its properties from the acrylonitrile. By changing the ratio of acrylonitrile to butadiene groups in the rubber it gives varying properties to the rubber, one of which is referred to as the shore hardness. This explains why it is important to get the correct O-rings when purchasing for a specific job.

Acrylonitrile is quite a nasty chemical before it in incorporated into plastics and rubbers. But when it is used to make acrylic plastics and rubbers and it is polymerised it takes on very different characteristics.

Below is the chemical structure of acrylonitrile and butadiene just to satisfy my inner-chemist (Structures taken from Wikipedia where you can read more about the chemical if you wish).

Over time, rubbers, even synthetic rubbers, perish and lose their physical properties that make them good as seals. So over time the O-rings swell and fill the rectangular void in the housing. This is why when you remove the old O-ring you may see that it has a square cross-section, when the new O-ring that you can purchase from Tractor Spare Parts Ltd has a round cross-section.

When the O-rings swell they go softer and it allows oil to pass through or around the seal, meaning that you visualise a leak on the outside of the selector shaft, as my customer has observed.

How to replace this O-ring

The way to approach this O-ring replacement is to remove the nut, washer, selector and flat washer first. Then you should be able to see the NT3383 PTO selector O-ring in the housing. Remove this O-ring and make sure all of it is out and that it is all clean.

When you have the new O-ring, we usually smear it with plenty of grease and put it back in the housing. Put the flat washer up against the new seal, and then replace the other items in the correct order – selector, washer and nut.

You can see the You Tube video that we put up on our channel by following this link.

It is as simple as that and now your PTO selector on your Nuffield or Leyland tractor should not leak.