It is always frustrating when your tractor stops, and you think it is due to a fuelling problem. Where do you start with solving this frustrating issue? What do you look at first? How do you even know if it is a problem with the fuel? What can be the causing these problems? Here I hope to give you an idea of where to start with this diagnosis and repair guide regarding when you think you may have a problem with your fuelling system.

First, everything I talk about here will be based on the Nuffield, Leyland, and Marshall tractor set-up, although there is no reason why a lot of the principles cannot be applied to other makes of tractors as well.

You know that there is a problem with the fuelling system on your tractor when the engine stops, but the engine will still turn over with the starter motor and there is no smoke or fumes from the exhaust. These symptoms suggest a fuelling problem.

How do you approach a fuelling problem?

You suspect that there is a fuelling problem but what is it that you can check first? There are quick, cheap and easy things that you can check first, as at the other end of the scale items such as injection pumps can be costly if they need replacing.

We always encourage customers to check easy and cheaper parts first as 80% of the time they will solve the problem, and at the end of the day it never does any harm to change a fuel filter.

Diesel bug

The first thing to establish is if you are getting any fuel to the engine. Blocked filters are the number one problem with fuelling. We find that in recent years the number one problem is ‘diesel bug.’ But what is diesel bug and what can we do about it?

Stored fuel deteriorates over time as it reacts with oxygen present in the air. Usually, fuel can be stored for up to a year without any problems, but we have seen an increase in fuel contamination as the proportion of biodiesel in fuel has increased. Diesel fuel now contains up to 7% biodiesel, which is great news for the environment, but bad news for anybody who wants to store fuel.

Petrochemical diesel does not attract water in the same way that biodiesel does. Biodiesel is hygroscopic, which means that it absorbs water from the atmosphere. Water can form in fuel tanks as it gets hot in the day and colder at night, meaning water condensates on the fuel tanks. This condensation is absorbed by the biodiesel. This water in the fuel together with the bio content of the fuel encourages growth of diesel bug.

Diesel bug is a bacterial growth that forms in diesel. The cells of the bacteria range from 0.3 to 60 micrometres in diameter and under perfect conditions these bacteria can double every 20 minutes. By doubling every 20 minutes one bacterium can turn into two million bacteria in just 7 hours!! You can see that once contamination takes place it does not take long to become a problem.

How do you know it is diesel bug contamination?

If you suspect you have Diesel bug, how do you know? There are several types of bacteria that can grow in diesel. Therefore, the contamination can look slightly different depending on which type you have a problem with. Diesel bug contamination can look like slime forming in the diesel. The colour of the slime can vary from dark brown to black. The contamination may also smell like rotten eggs.

Some things that you can look for with Diesel Bug contamination are as follows:

- Fuel filters being blocked regularly

- Sediment builds up in the fuel filters that looks like coffee granules

- Engines losing power

- A bad smell coming from the exhaust

- Black smoke coming from the exhaust

- Increased fuel consumption

- Difficulty starting the engine

How do I prevent Diesel Bug contamination?

Diesel bug can strike in both the fuel storage tank and in the fuel tank on your tractor. It is usually down to poor quality fuel storage where water can get in and fuel the bacterial growth. There are a few things that you can do to help prevent contamination:

- You can establish a fuel maintenance programme to remove any debris, water and dirt from your fuel. This could be in your storage tank and in the tractor itself. For example, our bulk storage tank has a 10-micron filter for water and dirt removal.

- Check the fuel is not in contact with zinc, copper and other metal alloys that can react with the fuel.

- Regular checks of the fuel tanks for damage and leaks.

- Ensure a regular turnover of fuel. Diesel bug grows if the fuel is allowed stagnate in the tank, for example if the tractor is not used very often, or if your bulk storage tank it too big for a regular refill. If the fuel is moving, then it doesn’t grow.

- Monitor vehicle issues and catch recurring issues early on

If you think that you may have Diesel bug then the only thing to do is to drain the fuel, treat and clean the tank and put clean fuel back in (either treated, filtered fuel or fresh fuel). There is no point putting fresh fuel back into a tank that has not been thoroughly cleaned.

That was a long-winded way of saying that Diesel Bug is now the number one cause of fuel problems in tractors, both new and old.

Change filters as Number One test

We always suggest that the first thing that you do when you suspect a fuel problem is to change the fuel filter. This is a quick, cheap and easy thing to do. We always advise that you keep a spare set of filters on the shelf anyway, so if you have a spare set, you can just change the fuel filter. Thankfully a lot of the Nuffield, Leyland and Marshall share the same fuel filter, so if you have multiple tractors, you may only need to stock one or two different filters.

Most commonly on the Nuffield. Leyland and Marshall tractors there is the short or the long metal canisters. The short filter is part number 37H1581 and looks like the proportions of a half-portion bean tin.

The long metal canister fuel filter fitted to the Leyland and Marshall tractors is the part number 37H7937 fuel filter. This metal canister has the same proportions as a tin of food but is slightly larger.

Most times this will solve the problem and if there is no permanent contamination being introduced to the system (i.e. diesel bug in the fuel storage tank), then this should solve the problem.

Occasionally rust or dirt will break off these older vehicles and flow through the fuel system and be caught in the fuel filter – it is what they are there for.

When to replace the fuel lift pump

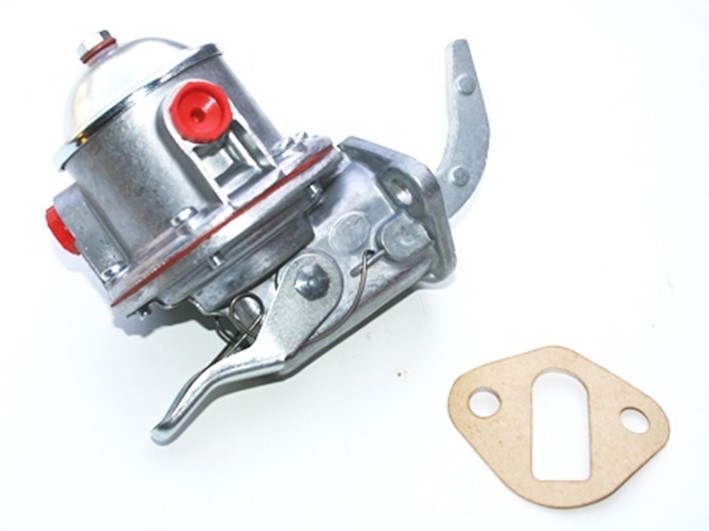

Fuelling problems can be due to a faulty lift pump, and by replacing the fuel lift pump this is an inexpensive way of checking the fuelling system thoroughly.

You need to know that if you are getting fuel to the lift pump, then if fuel is getting there does it work correctly.

A worn lift pump will present itself that the engine will run well when there is a full tank a fuel in the tractor but will faulter and stop when the fuel inside the fuel tank gets low. This is because the pressure of the fuel level in the tank being above the fuel injection pump keeps it working when the fuel level is above the injection pump. But when the level of the fuel is physically below the injection pump it does not receive the fuel from the lift pump. The engine then fails as there is no fuel reaching the injection pump and the engine stops.

To check the lift pump, you can break (slacken) the highest point in the fuel system and manually prime the pump. This should send fuel (and possibly air) out of the slackened fitting. After 10 to 20 seconds of pumping the lift pump you should just have fuel coming out with no air. If you still have air coming out after this time this could be a sign that the diaphragm in the lift pump has been damaged and needs replacing.

You may also find that the oil level goes up as fuel goes into the sump.

When to replace the fuel injection pump

Replacing the fuel injection pump is only really an option once all the fuel system up to this point has been checked. Check the fuel lines, change the filter, check the lift pump etc. The fuel injection pump is the costliest part of the fuel system and therefore you only want to be changing it when you have ruled out everything else as a possible cause first.

You will find that when the fuel injection pump fails, no matter if it is a rotary DPA pump or a Minimec inline pump the pump may fail either on stop or the engine speed runs flat our and can only be controlled by the stop cable. This is a definite sign that the injection pump needs replacing.

There are two types of fuel injection pumps – rotary pumps and inline pumps.

Rotary pump

The Rotary pump is also called a DPA pump and DPA stands for distributor pump A. This DPA pump was designed for it’s relatively low manufacturing costs, but also because this type of pump is suitable for operation at higher speeds than the conventional in-line plunger pumps because DPA injections pumps do not have delicate valves and springs.

The rotary pump has, as the name would suggest, more of a circular design with the outlet for the fuel being at the back and positioned in a circle. The type of pump works by having a single injection cylinder which is driven from an axial arm plate, which injects into the individual fuel lines via a rotary distribution valve.

Inline pumps

The inline pumps, especially in relation to the Nuffield, Leyland and Marshall marques, are often referred to as Minimec pumps or Simms inline pumps.

These types of pumps can be identified by the fuel outlets positioned on the top of the pump which are all in a straight line.

Simms inline pumps work because each cylinder in the inline pump operates on its own. This does, however, have the drawback that each cylinder has the potential to fail on its own.

Who are CAV, Lucas and Simms?

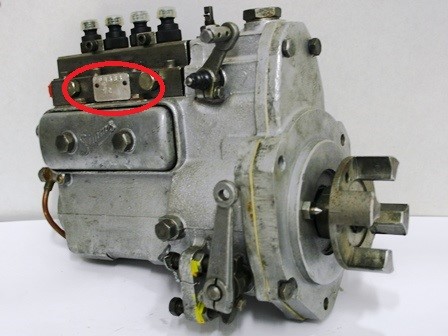

When you are looking at replacing the injection pump on your Nuffield, Leyland or Marshall tractor we will ask you for the number from the side of the pump. You may notice that if it is a rotary pump then this plate has CAV on it; if it is an inline pump, it may have Simms written on it. These are the manufacturers of the pumps.

Interestingly both CAV and Simms were taken over by Lucas.

CAV is a company started by C.A. Vandervell and in 1931 CAV started a partnership with Robert Bosch and they started making injection pumps for the diesel industry. Lucas bought out Bosch’s interest in 1937 and the company became CAV Ltd in 1939. In 1978 the company name changed to Lucas CAV.

Simms started manufacturing diesel fuel injectors in the 1930’s. Simms as a company acquired many other companies over the time and by 1968 Simms itself was taken over by Lucas and it was integrated into the CAV division.

Pump numbers

When looking to price up or purchase a fuel injection pump we will ask you for the numbers off the side of the injection pump. This number tells up about which pump body it is, and it tells us about the internally fuelling setup of the pump. We need to make sure that what we are sending you a replacement pump which is the same as what you already have on the tractor. The injection pump and the injectors should be matched so we need to ensure that we are replacing like for like.

Below are some example numbers that you may see. They are usually on a metal plate riveted onto the side of the pump. This is a rotary CAV pump, and it has a blue CAV plate on the main pump body. The pump number is letter stamped onto this plate.

This pump below is an inline pump, and the pump number is on the rectangular metal plate that I have highlighted in red.

Typical numbers that you would find for Nuffield, Leyland and Marshall tractors are as below.

|

Number on pump |

Diesel Engine compatibility |

Model tractor |

Rotary or Inline |

Leyland part number and link to purchase |

|

3248F530 |

BMC 950 |

BMC Mini tractor |

Rotary |

|

|

3247E090 3247F090 |

Leyland 1500 |

Leyland 154 Nuffield 4/25 |

Rotary |

|

|

P4801 |

BMC 3.8 TD Leyland 4/98 |

Nuffield 4/65 Leyland 384 Leyland 270 Leyland 272 Leyland 472 Marshall 702 Marshall 704 |

Inline |

|

|

P4824 |

BMC 2.8 TD |

Nuffield 3/45 |

Inline |

|

|

P4584 |

BMC 3.8 T BMC 3.8 TA |

Nuffield 460 Nuffield 10/60 |

Inline |

|

|

P4586 |

BMC 2.8 T BMC 2.8 TA |

Nuffield 3/42 Nuffield 10/42 |

Inline |

|

|

P5102 |

BMC 3.4 TD |

Leyland 344 |

Inline |

|

|

3249F850 |

Leyland 4/98 |

Leyland 270 |

Rotary |

|

|

3269F450 |

Leyland 6/98 |

Leyland 285 Leyland 2100 Leyland 485 Leyland 4100 |

Rotary |

|

|

3342F260 |

Leyland 4/98 NT |

Leyland 262 Leylan 462 Leyland 272 Leyland 472 Marshall 602 Marshall 604 Marshall 704 Marshall 704 |

Rotary |

|

|

3249F690 |

Leyland 4/98 |

Leyland 255 |

Rotary |

|

|

3342F300 |

Leyland 4/98 DT |

Leyland 262 Leyland 462 Marshall 602 Marshall 604 |

Rotary |

|

|

3230F410 3230F350 |

Perkins AD3.152 |

Leyland 245 Leyland 253 |

Rotary |

|

|

3342F760 |

Leyland 4/98 TT |

Leyland 282 Leyland 482 Marshall 802 Marshall 804 |

Rotary |

|

|

SPE4A75S364 |

BMC 3.4 T |

Nuffield 4DM |

Inline |

|

|

SPE4A75S619 |

BMC 3.4 T BMC 3.4 TA |

Nuffield 4DM Nuffield Universal 4 |

Inline |

|

|

SPE3A75S621 |

BMC 2.6 T |

Nuffield 3DL Nuffield Universal 3 |

Inline |

|

|

P4662 |

BMC 3.8T BMC 3.8 TA |

Usually, marinized engines |

Inline |

Once you have fitted a new injection pump

It is imperative that all fuel lines and the filter is clean before fitting a new or a reconditioned injection pump. Here at Tractor Spare Parts Ltd, we offer a 12-month warranty on reconditioned injection pumps, but only if only clean fuel has passed through the pump. We find that when injection pumps come back to us with problems, it is mostly due to dirty fuel causing problems.

Cleanliness is next to Godliness when it comes to the fuel system of your tractor.