As I am writing this blog, we are at the beginning of a cold snap here in the UK. It might not be as cold as many other parts of the world who would laugh in our face at -6 oC, but it is cold enough.

Here at Tractor Spare Parts Ltd, we are a little bit different to many other tractor parts suppliers in that we have the knowledge to help you get the parts that you purchase from us fitted to your tractor. I had a phone call from a customer this morning, a customer who I have spoken to quite regularly over the past six months or so. He has a Leyland 270 and this morning his question was about the cold start cable on his tractor. He just could not work out how the parts go together, even though he thought everything was present. Being the helpful person that I am (?) I offered a quick page from the parts book and thought it would just be a case of sending it in an email and it would be sorted. However, it turns out that this was a classic case of the Leyland parts books being less than helpful. So, I thought that this was a perfect opportunity to document how this linkage goes together.

What is a cold start and why do we need to help an engine start in the cold?

Starting an engine in cold conditions is harder than starting an engine when it is warmer, or when the engine has been up to running temperature. There are several reasons for this:

- The engine compression is higher as the lower temperature makes ignition more difficult.

- Lower temperatures cause the oil in the engine to be more viscous, meaning that it is more difficult to circulate the oil around the engine.

- Air becomes denser as it cools down, and this affects the air to fuel ratio, which in turn affects the flammability of the mixture.

- Fuel becomes slightly thicker at lower temperatures as the longer carbon-chain length components are more like a paraffin wax. The average chemical formula of diesel is C12H23 (12 carbon chains in the length of the molecule), but the reality is that the components range from C10H20 (10 carbon chains in the length of the molecule) to C15H28 (15 carbon chains in the length of the molecule). The longer the carbon chain is, the more it is more like a wax, rather than a liquid. So, at lower temperatures these longer carbon chains cause the diesel to become more viscous. (Can you tell I studied a lot of chemistry at university? I hope it is not too dull, I could go on and on in more detail but I will restrain myself here)

These physical changes that take place to the components of the engine, when it is colder, combine to make it more difficult to start an engine when it is colder.

How do we get around this to allow engines to start in the cold?

There are several different ways that engineers have gotten around this problem of starting engines in the cold, and all of them address one of the above points to try to make ignition more likely.

Glow plugs

Many diesel engines use glow plugs to heat the combustion chamber of the engine, which improves the conditions inside the engine and makes ignition more likely. It heats the air to counteract the denser colder air and how this affects the air to fuel ratio.

This approach is what BMC and Leyland have done with the BMC 950 Diesel engine, and the Leyland 1500 and Leyland 1800 engine. These engines have four glow plugs, part number AG39, which are located in the cylinder head and heat up the air in the combustion chambers.

Heater Plugs

Another solution to starting engines in the cold is to use a thermostart, also known as a Heater plug or block heater, which is located in the air intake manifold and warms the air up before it enters the combustion chambers.

This approach is what Leyland have done on the middleweight range of tractors from the Leyland 245 up to the Leyland 2100 as well as in the Harvest Gold range of Marshall tractors from the Marshall 502 up to the Marshall 100.

Starter Motors

More modern starter motors, such as those fitted to the Leyland and Marshall tractors, have high revs, which improve the chances of ignition. Having a good working starter motor can really help in cold conditions, even if it is not a direct solution itself.

Easy Start

I hate to talk about Easy Start as a way of starting engines in the cold. Easy Start is a volatile liquid which is sprayed into the engine and allows it to turn over on cold days. It was originally designed to help start a worn out engine, or an engine with fuel leaks etc.

It is because of this volatile liquid which is easily ignited in the combustion chambers, which means that the engine starts.

We DO NOT recommend the use of Easy Start starting fluid on the BMC or Leyland engines.

Many people use this starting fluid when the engines need to be rebuilt too – NOT A GOOD IDEA!

That is all I have to say on that subject and I will now move on. ?

Cold Start Cables

Many tractors have a cold start cable, which as the name suggests aids starting the engine in colder conditions.

This cold start cable is usually located on the dash console or near the steering column, and it usually has a black pull knob, unlike the stop cable which has a red knob.

This cold start cable has an inner cable and an outer cable. The inner cable is attached to the fuel injection pump and helps to control the amount of fuel entering the engine when it is pulled. When the cold start cable is activated, it increases the fuel volume that is injected into the bores, which changes the air to fuel ratio and compensates for the denser air, and helps ignition of the fuel.

How is the cold start cable attached?

The cold start cable, part number ATJ9190, is used on the DPA pumps which is a rotary pump (you can read more about the types of pump in my fuelling problems blog in this link here) which is fitted as an option on the middleweight range of tractors.

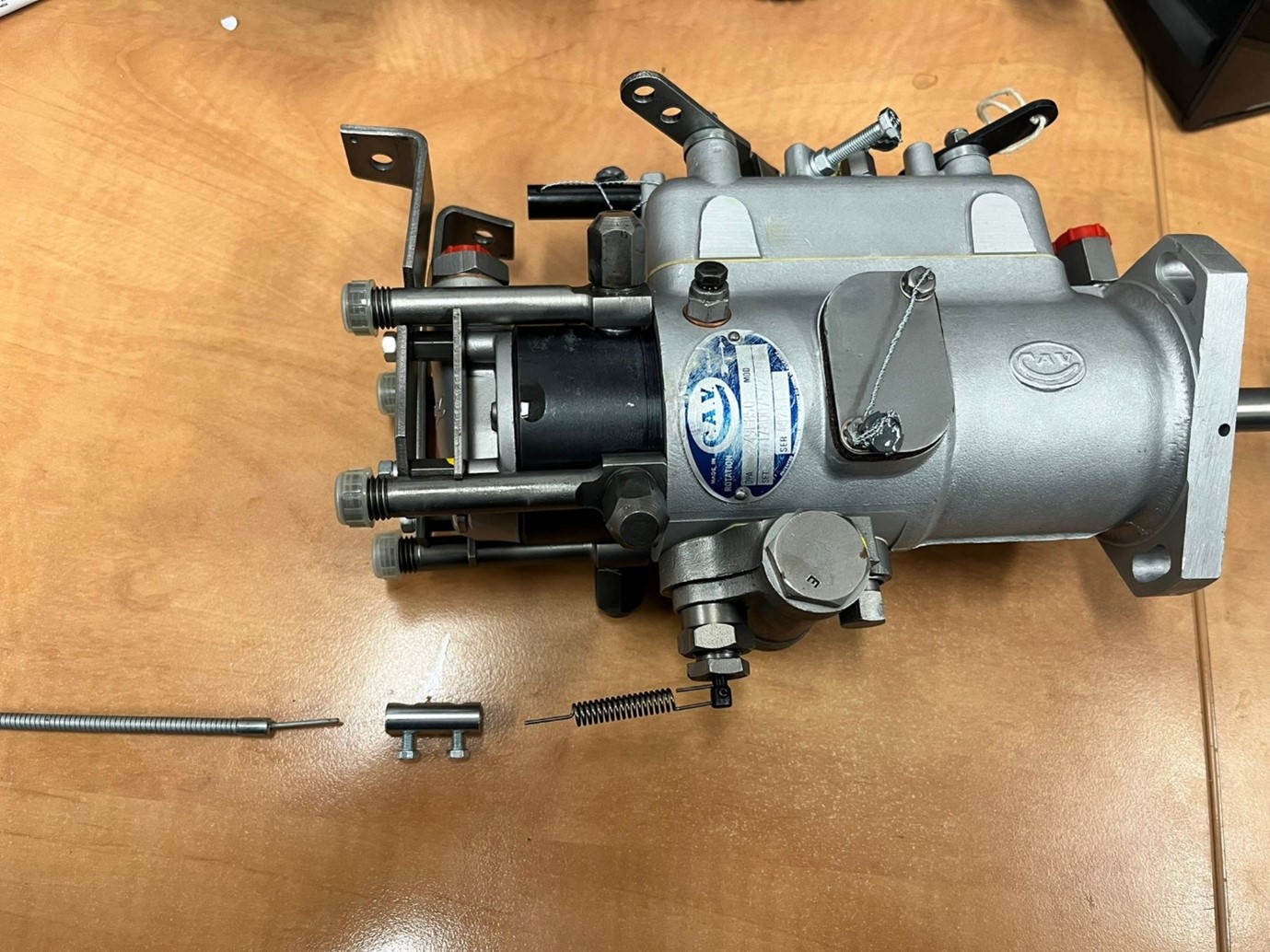

The customer who rang up asking about the location of the cold start cable had a Leyland 270 with the DPA pump, so I am going to use this Leyland 270 pump as an example. The Leyland 270 tractor can either be fitted with the Simms inline pump, also known as the Minimec pump, which is Leyland part number 13H6140 and marked as pump number P4801, or it can be fitted with the DPA rotary pump which was manufactured by CAV and has Leyland part number 83H490 or CAV part number 3249F850.

The DPA pump has the cold start cable attached to the X retard device at the bottom of the pump.

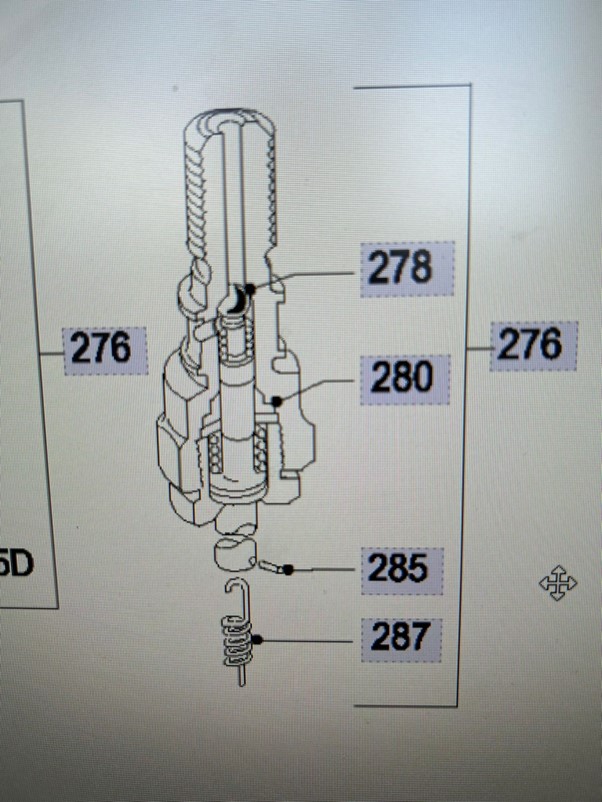

The retard device only moves a small amount and therefore to give the illusion of it moving, and also to stop the cable from pulling on it too much, there is a spring and clamp block mechanism. This X Retard decides to work by controlling a small ball bearing (No 278 on the diagram below) inside the pump, which in turn controls the amount of fuel that the pump gives out.

The cold start spring is a small spring with a hook on one end and a straight leg on the other end. This spring is part number 37H825 (No 287 in the diagram above) and is a UK made spring which is readily available to purchase from our website – follow this link. This spring attaches to the bottom of the fuel pump, and the hook that is on the spring has to attach around the pin (No 285 on the diagram above) that runs through the centre, as in the pictures above and below.

Next, the straight end of the cold start spring goes into the clamp block which is part number 3H950, and again is readily available to purchase on our website – follow this link.

This clamp block is a cylindrical clamp with 2 screws through it: one for the spring and one for the cold start cable. The straight end of the spring goes into the clamp black and attaches using the screws.

The inner cable of the cold start cable then attaches to the other end, and it is routed to the dash.

The pictures below show the individual components lined up and attached together.

All of these parts, as well as service exchange fuel injection pumps are available on our website, www.tractorspareparts.co.uk. Just select your model of tractor and follow links to engine parts then fuel system parts.